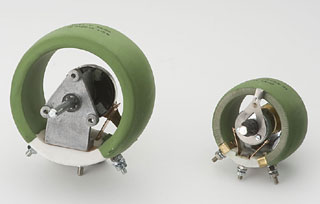

TC MODEL

Home » Products » POTENTIOMETERS AND TOROIDAL REOSTATS » TC MODEL

GENERAL CHARACTERISTICS

These rheostats are designed for installation behind control panels and are high strength, with the ability to sustain considerable temporary accidental overloads.

The slightly spaced spiral winding, generally in constantan, is spiral wound on a ceramic toroid with compartments obtained for the various attachments.

The winding is covered with ceramic cement and subsequently fired in a kiln at 400°C.

The result is a single compact body capable of supporting the thermal stress resulting from its use.

A slider runs on a track created on one of the ring bases made of a double sheet of phosphorous bronze or stainless steel foil, for the sliding contact.

The ends of the winding are connected to the terminal strips, which are fixed with output terminals.

Any resistance value can be realised within the values indicated in the table.

- Winding in sections

- Mounting several coaxial rheostats

- Application of one or more position micro-switches

- Zero exclusion (interrupted)

- Special double extrusion, square shaft design.

- Continuous rotation

- Shaft blockage device

- Intermediate fixed sockets

For single section standard rheostats (adjustment ratio < 2), specify the desired ohm value and the maximum current, or better still, the model and ohm value.

For rheostats with several sections (max 5), it is necessary to indicate the total ohm value and the maximum currents (rheostat disengaged) and minimum current (rheostat entirely inserted).

Sub-division of the resistance is generally performed with hyperbolic law.

In the event a particular division of the resistance is required, it is sufficient to indicate the angle at the centre of each sector and the relative ohm value.

Contact us

Use the form below to request information, offers and quotes relating to ItalOhm products. We will reply as soon as possible.